Wholesale Engineered Veneer Suppliers You Can Trust

When it comes to sourcing engineered veneer for furniture production, working with trustworthy wholesale suppliers is crucial. VUNIR, for example, is known for its commitment to quality and reliability in providing a wide range of engineered veneer options. By partnering with reputable suppliers like VUNIR, furniture manufacturers can have peace of mind knowing that they are getting consistent and high-quality materials for their products.

Why Consistent Engineered Veneer Matters in Furniture Manufacturing

Consistency in engineered veneer plays a significant role in the overall quality and appearance of furniture products. Imagine a furniture piece with inconsistent veneer patterns or colors - it would look unprofessional and unappealing. By using consistently manufactured engineered veneer from suppliers like VUNIR, furniture manufacturers can ensure that each piece they produce meets the same high standards of quality.

In addition to aesthetics, consistent engineered veneer also contributes to the durability and longevity of furniture products. Veneer that is uniform in thickness and composition will provide better structural integrity and resistance to wear and tear over time. This means that furniture made with consistent engineered veneer is more likely to withstand daily use and maintain its appearance for years to come.

Moreover, consistency in engineered veneer simplifies the manufacturing process for furniture makers. When each sheet of veneer is uniform in quality, size, and texture, it streamlines production and reduces waste. This efficiency not only saves time and money but also ensures that every piece of furniture coming off the production line meets the same high standards of craftsmanship.

choosing a reliable wholesale supplier like VUNIR for consistent engineered veneer is essential for furniture manufacturers looking to produce high-quality, durable, and visually appealing products. By prioritizing consistency in their materials, manufacturers can create furniture pieces that stand out in the market and satisfy customer expectations for years to come.

Engineered Veneer vs. Solid Wood - Which is Better?

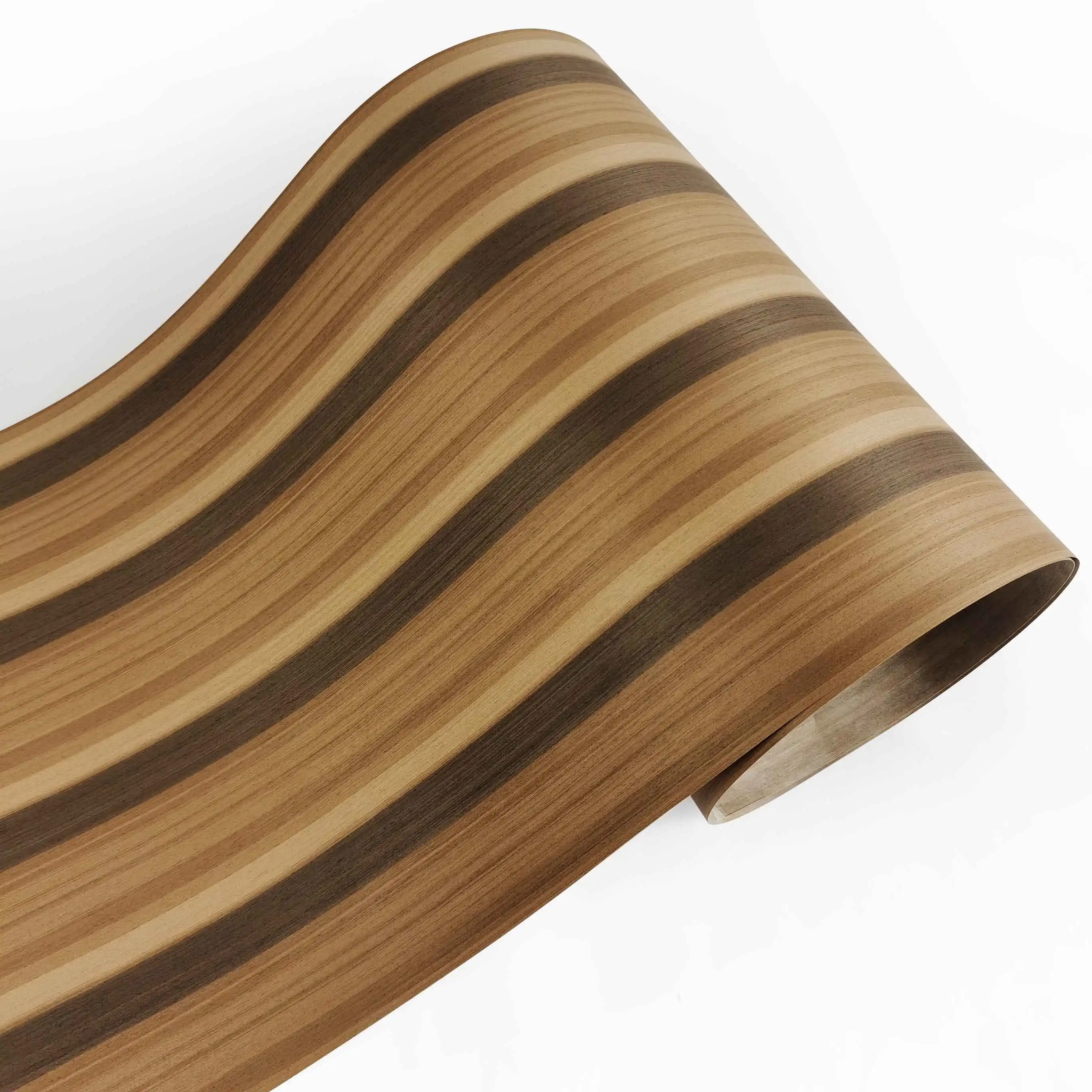

When it comes to choosing between engineered veneer and solid wood, there are several factors to consider. Engineered veneer is made by stacking thin layers of wood together, while solid wood is made from a single piece of wood. One advantage of engineered veneer is that it is more stable and less prone to warping or cracking than solid wood. This is because the layers of wood are glued together in different directions, which helps to counteract the natural movement of wood. Additionally, engineered veneer is more environmentally friendly, as it allows for more efficient use of wood resources. On the other hand, solid wood has a more traditional and natural look, which some people prefer. Ultimately, the choice between engineered veneer and solid wood depends on individual preferences and needs.

Questions to Ask When Buying Engineered Veneer in Bulk

When artificial wood veneer purchasing engineered veneer in bulk, there are several important questions to ask to ensure that you are getting a high-quality product. First, it is important to inquire about the consistency of the veneer. Veneer that varies in thickness or color can affect the overall look of a project. Additionally, ask about the durability and longevity of the veneer. It is important to choose a product that will withstand wear and tear over time. Another important question to ask is about the sustainability of the veneer. Ensure that the wood used to make the veneer is sourced from responsibly managed forests. Lastly, inquire about the availability of different finishes and styles to ensure that you can find the perfect veneer for your project.

Engineered Veneer Trends in the Wholesale Market

In the wholesale market, there are several trends spliced veneer emerging in the world of engineered veneer. One trend is the growing popularity of exotic wood species. Engineered veneer allows for the replication of rare and expensive wood species at a more affordable price point. Another trend is the use of innovative technology to create unique and customizable veneer designs. Digital printing and laser cutting techniques are being used to create intricate patterns and textures on veneer. Additionally, there veneer splicing is a trend towards sustainability and eco-friendliness in the wholesale market. Consumers are increasingly looking for veneer products that are made from recycled or renewable materials. Overall, the wholesale market for engineered veneer is constantly evolving to meet the needs and preferences of consumers.